A system of high pressure tubing, hoses, fittings and valves provides a network of checks and balances that direct and regulate the flow of compressed air to the various brake chambers that ultimately stop the vehicle. It also provides the driver with important kinesthetic feedback and visual and acoustic feedback that helps prevent crashes and other accidents.

A treadle or foot valve mounted on the floor of the cab or in the firewall of the cab is operated by the driver to apply the tractor and trailer brakes. The more the driver presses on the foot valve, the more air it lets through to the service line that controls how forcefully each brake is applied.The air tanks, three per tractor and usually two per trailer, store pressurized air until it is needed to actuate the brakes. A gauge connected to each tank tells the driver how much pressure is in each air tank.

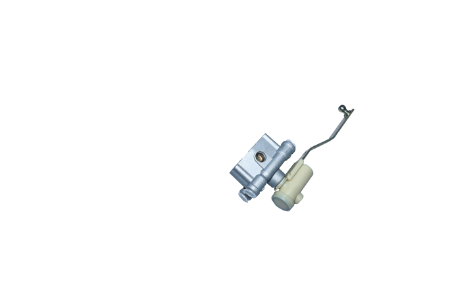

In a dual-circuit air brake system, the driver can control the application of the spring brakes by a separate relay valve, which merges air from the primary and secondary reservoirs through a two-way check valve. This prevents air-loss from only one braking circuit from triggering the spring brakes to automatically apply and prevents grinding to a halt in an unsafe location.Other components in the air brake system include check valves, which prevent pressurized air from re-entering the compressor when it is not running. An automatic drain in the air tank can be used to remove air in cold weather, reducing the risk of ice formation inside the system.